What we Offer

From full material packages to installation support, we deliver corrosion-resistant systems engineered to match your chemistry, concentration, temperature, and abrasion profile.

Acid & Carbon Brick Systems

ASTM C279 Type II/III acid brick and specialty carbon brick solutions designed for towers, reactors, floors, and trenches—paired with the right mortar and membrane for long-term protection.

Corrosion-Resistant Coatings

Rubber linings, FRP/dual-laminate systems, and thermoplastic membranes for tanks, ducts, and vessels—engineered for chemical compatibility and durability.

Engineered refractory linings

At WD Equipment, we don’t sell “one-size-fits-all” materials.

We design and install complete protective lining systems that match the exact chemical, mechanical, and thermal conditions inside your plant.

Project Review & Consultation

Bills of material that cover brick, mortar, anchors, membranes, expansion joints, and QA tools—tailored to your process requirements and field conditions.

40+Years Experience

10+Suppliers

6+Industries Services

About us

Expertise in Industrial Refractory Solutions

WD Equipment specializes in protecting steel and concrete assets exposed to the toughest conditions—high temperatures, corrosive acids, abrasive slurries, and thermal cycling.

With decades of engineering insight, we design and supply systems that combine acid brick, carbon brick, rubber linings, and FRP/dual-laminate technologies. Every solution is tailored to the customer’s specific chemistry, concentration, and operating profile, ensuring maximum durability and compliance with ASTM standards.

Whether it’s an absorber tower, phosphate reactor, or a trench subject to constant erosion, WD Equipment delivers proven, engineered protection where performance cannot be compromised.

Our Services

Every application is different, and WD Equipment approaches each project with tailored engineering solutions.

We analyze your process conditions —

chemistry, concentration, temperature, abrasion, and thermal cycles—to design brick, lining, and membrane systems that meet ASTM standards while delivering maximum performance and service life.

Products & Services

Refractory Coatings

Our phosphate-bonded refractory coatings are engineered for superior resistance to heat, abrasion, and chemical attack. They extend the service life of critical equipment in phosphate and chemical processing environments.

Chemical Resistant Brick & Tile

We supply ASTM C279 Type II/III acid brick designed for maximum chemical resistance in towers, tanks, and trenches. Paired with the right mortars and membranes, acid brick systems deliver durable protection against aggressive acids.

Corrosion Resistant Coatings

From rubber linings to FRP/dual-laminate systems, our solutions safeguard equipment exposed to a wide range of corrosive chemicals. Each lining is tailored to your service environment for long-term reliability and compliance.

Durable Expansion Joints

Our expansion joints are designed to handle thermal cycling, pressure changes, and chemical exposure without failure. They ensure system flexibility and maintain integrity in the harshest operating conditions.

Expert Consultation Services

WD Equipment’s team provides technical guidance on selecting the right materials, mortars, and linings for your specific application. We partner with engineers and plant managers to design systems that reduce risk and maximize uptime.

Mortar Systems

Our engineered systems combine proven materials, precision design, and quality assurance tools to deliver unmatched performance. Customers benefit from longer service life, reduced downtime, and confidence in compliance with industry standards.

Get in touch

Have a project or question? Our team is ready to help with material selection, system design, and technical support.

Insights & Resources

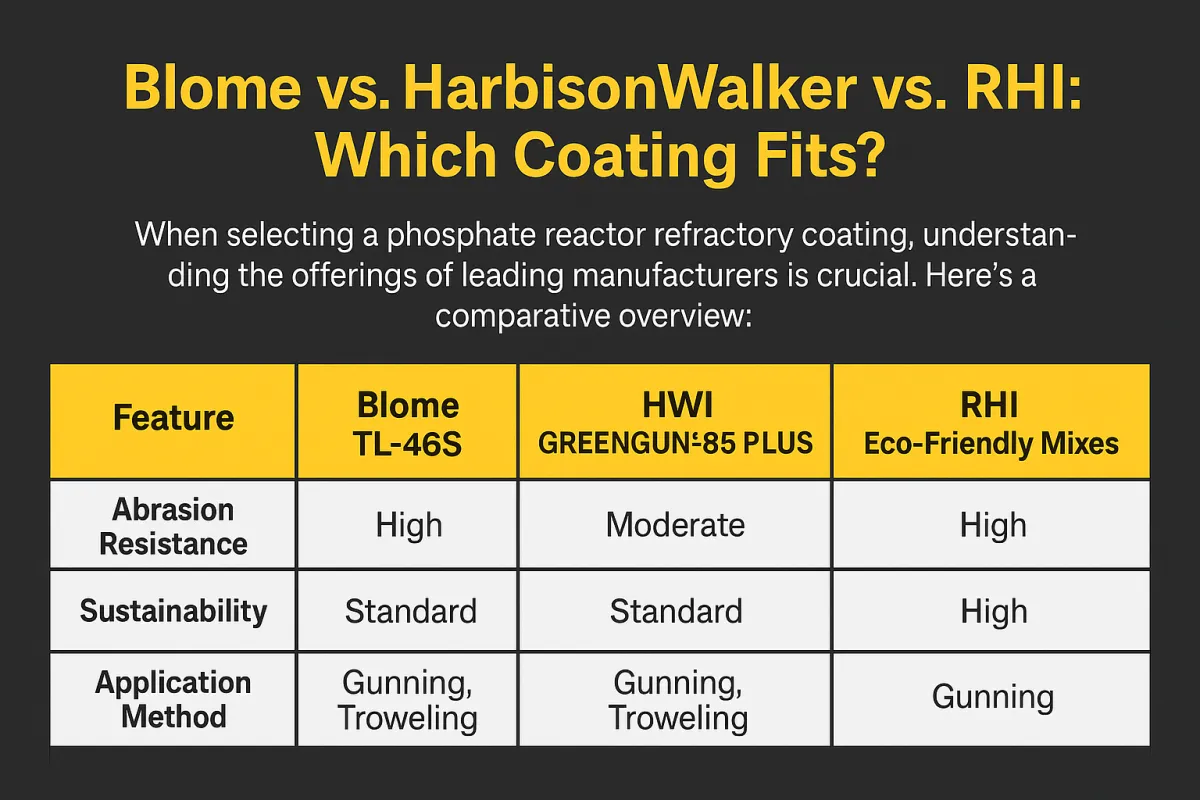

Blome vs. Harbison Walker vs. RHI: Which Coating Fits?

Blome vs. Harbison Walker vs. RHI: Which Coating Fits?

When selecting a phosphate reactor refractory coating, understanding the offerings of leading manufacturers is crucial. Here's a comparative overview:

Blome International: Known for its TL-46S Novolac Epoxy, Blome provides coatings that exhibit outstanding abrasion, erosion, and impact resistance due to their uniquely flexible, ceramic-filled formulation. This makes them suitable for aggressive environments.

HarbisonWalker International (HWI): HWI offers a range of products, including GREENGUN®-85 P PLUS, designed for the toughest environments. Their products are known for durability and performance in high-temperature applications.

RHI Magnesita: RHI's offerings include eco-friendly gunning mixes that have a drastically reduced PCF (Product Carbon Footprint) of up to -85% compared to equivalent standard mixes, aligning with sustainability goals.

Comparison Table:

Conclusion: The choice between these manufacturers depends on specific plant needs, including environmental considerations, application methods, and desired durability.

Focus on the key takeaways: Identify the most important findings, conclusions, or implications

Be concise and specific: Summarize each point in a single sentence

Tailor to your audience: Consider the audience’s background knowledge and interests